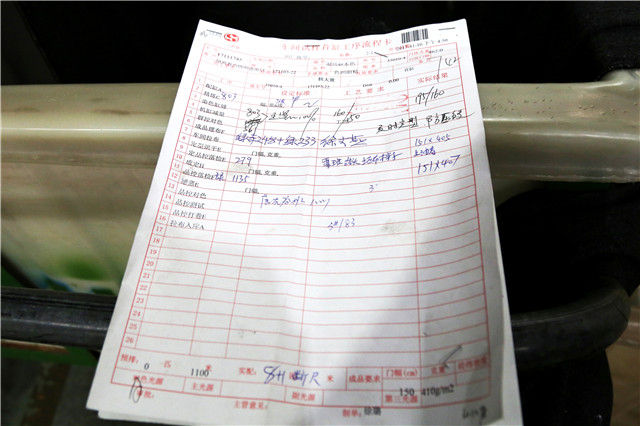

Including product number, color number, dyeing quantity, special dyeing requirement, complete production plan data sheet.

Prepare grey cloth needed, and arrange transportation to production department.

Pull Grey cloth into the dyeing factory warehouse, input storage data.

Arrange production plan according to production demand.

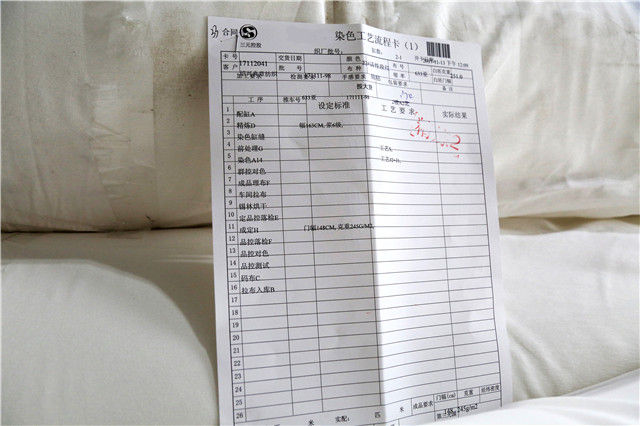

Carry out the production process card, including production standards, production engineering etc.

When the production plan card is received, match the number of the vats.

The process of clean the stain treatment to make the dyed cloth clean and clear.

High temperature pre shrinking, standardize the width and weight.

Dehydration process, remove the water in the cloth.

After dehydration, the next process is carried out with the scutcher, make cloth neat.

Dry the cloth with high temperature on the setting machine.

The door width, gram weight, cloth flatness fixed shape.

Singeing is carried out for the purpose of removing the loose hairy fibers protruding from the surface of the cloth, make it smooth and clean.

Alkali treat according to the weight and feel of the finished fabric.

Dyeing is the process of adding color to textile products like fibers, yarns, and fabrics.

After the dyeing is completed, the cloth needs to be cleaned and dehydrated.

After dehydration, the next process is carried out with the scutcher, make cloth neat.

Calibration setting relates to the handle, shrinkage, weight, width, color, surface roughness, texture clear and full.

After full decatizing, the cloth is compact and smooth, the color is bright, clear and full, and make the garment showing good drape shape.

Measure meters of per cloth, and label it.

Take quality trimming of the cloth before entering the warehouse.

The inspection procedure is to classify the quality of the fabric and label them.

Roll up each piece of cloth, so that the warehose can be well placed and the cloth face is not wrinkled.

The product is packaged well into the warehouse and placed in the planning position.